I’ve mentioned loafing sheds a few times so I thought I would go into more detail about why they pop up in my plans so often. Where I am located, the winter is short (maybe 3 months top) and the worst aspect is not snowfall, but ice and wind. Horses need shelter from rain even more and loafing sheds are easy to construct because of the simple roofline construction. They can be expanded in length quite easily and are still cheaper then a traditional barn frame because of not needing large trusses.

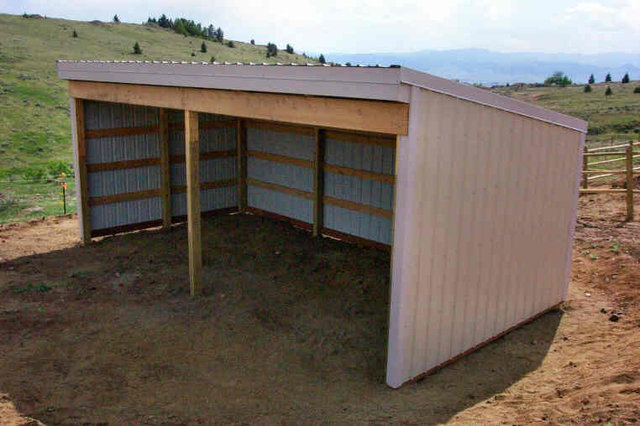

Depending on the roof line it could be simple such as this slope (simplest roof construction, requires a pitch for rain – this example needs to have the interior lined with plywood to protect horses when kicking):

A more decorative overhang that takes a bit more carpentry skills (this overhang provides runoff further away from the horse shelter; and it still needs to have the interior lined for protection):

For interior details on this roof read this later post with photos on how the joists are done.

If you are in a hotter climate then myself, mare motels are even more open, just providing a roof for shade and rain protection. These are generally built with pipe support and metal roofing.

Things to consider:

* If money was no object, I would do my run in sheds in concrete blocks (best option for cold climates too and maximum durability). I was stabled at a race farm for a short period that had these and the insulation is notably cooler in summer and more protective in winter. Concrete would also need to lined in the interior for kick protection.

* The base pad of your loafing shed needs to be higher then the surronding area to allow run off. I have seen people not put in the money for the foundation – the area gets worn down with usage, becoming lower and collecting water, urine etc… It’s very important to have a pad of dirt, screenings and gravel (if you are using horse mats) to provide appropriate sloping away from the unit.

* At one ultra cheap boarding facility, I did see someone put in a loafing shed that was not anchored into the ground. During the first windstorm, the shed completely FLIPPED OVER! Can you imagine those poor horses!? A rule of thumb: the post should be in the ground 1/3 of it’s total length.

* An auger can be rented to drill holes in the ground for your posts if you don’t want to do it the old fashioned way (post hole digger!). Rental equipment places offer a hand held job (be prepared to get jolted!) that is gas run and they also rent out those that attach to a tractor. IMO the rental places can be difficult to rent one because fence building companies grab them up in the summer (be sure to line up early for your rental and rent on a weekday if possible); and the tractor attached augers are not as precise as I would like.

* In my area, most run in sheds and loafing sheds are finished out with metal siding. If you call and look around, you can find metal siding SECONDS – colors that were not quite accurate, orders that were not paid after being requested, or were returned by the consumer to the factory. This can offer you substantial discounts from retail if you are flexible about color.

* Metal siding, like many other materials (other then wood) will need to be lined. I know of two instances where unlined, metal loafing sheds caused serious harm: death to a foal that sliced it’s leg off and it had to be euthanized; and a mare who kicked through and sliced her leg, causing permanent lameness due to muscle and bone loss.

Plywood can be found at savings on Craigslist where roofers will often post stock for sale. I would opt for at least 3/4″, exterior ply if you can find it.

* Before lining with plywood, considering placing insulation between the metal and plywood. We did some insulation in a barn area and it made a huge difference! Quite unbelievable in how big a difference it made in terms of comfort. Check out Craigslist for folks selling off the end of batting rolls or check with a construction firm for ends and seconds for savings.

* While placing the loafing shed off in the middle of the field may seem like a great idea – it’s not. This was the situation at our former boarding stable – the difficulty arises in that you have to walk across the field to feed in the rain/snow, and if you need to make it a stall due to an emergency (like we did when BigT broke his pelvis), you are far away from any access point.

If a loafing shed is your only option for stabling, place it where you can convert it to a stall or run in paddock in case of medical or dry lot need. Here free standing panels are assembled to allow limited movement.

Of the construction books I have on stable construction the book: Building Small Barns, Sheds and Shelters by Monte Burch gives the best technical details on roof construction, even though it has limited info on run-in or loafing sheds.

Pingback: Shedrows for horses « Horse Ideology

Pingback: Barn design: 3 separate pastures « Horse Ideology

Pingback: 2010 in review « Horse Ideology

Pingback: Barn design: 4-stalls, L-shaped with flow « Horse Ideology

Pingback: More horses need a parallel stall arrangement « Horse Ideology

Pingback: Barn Design: Shedrows for horses | horseideology